Comprehensive Business Strategies in Electronics and 3D Printing Industries: Unlocking Growth with Bulk Material Handling Solutions

In the rapidly evolving landscape of modern technology, businesses operating within the realms of electronics and 3D printing are at the forefront of innovation. These sectors not only drive technological advancements but also present unique challenges and opportunities for entrepreneurs and established companies alike. Among the various operational facets that determine success, effective bulk material handling stands out as a pivotal element that influences efficiency, safety, and profitability.

An In-Depth Look at the Electronics and 3D Printing Sectors

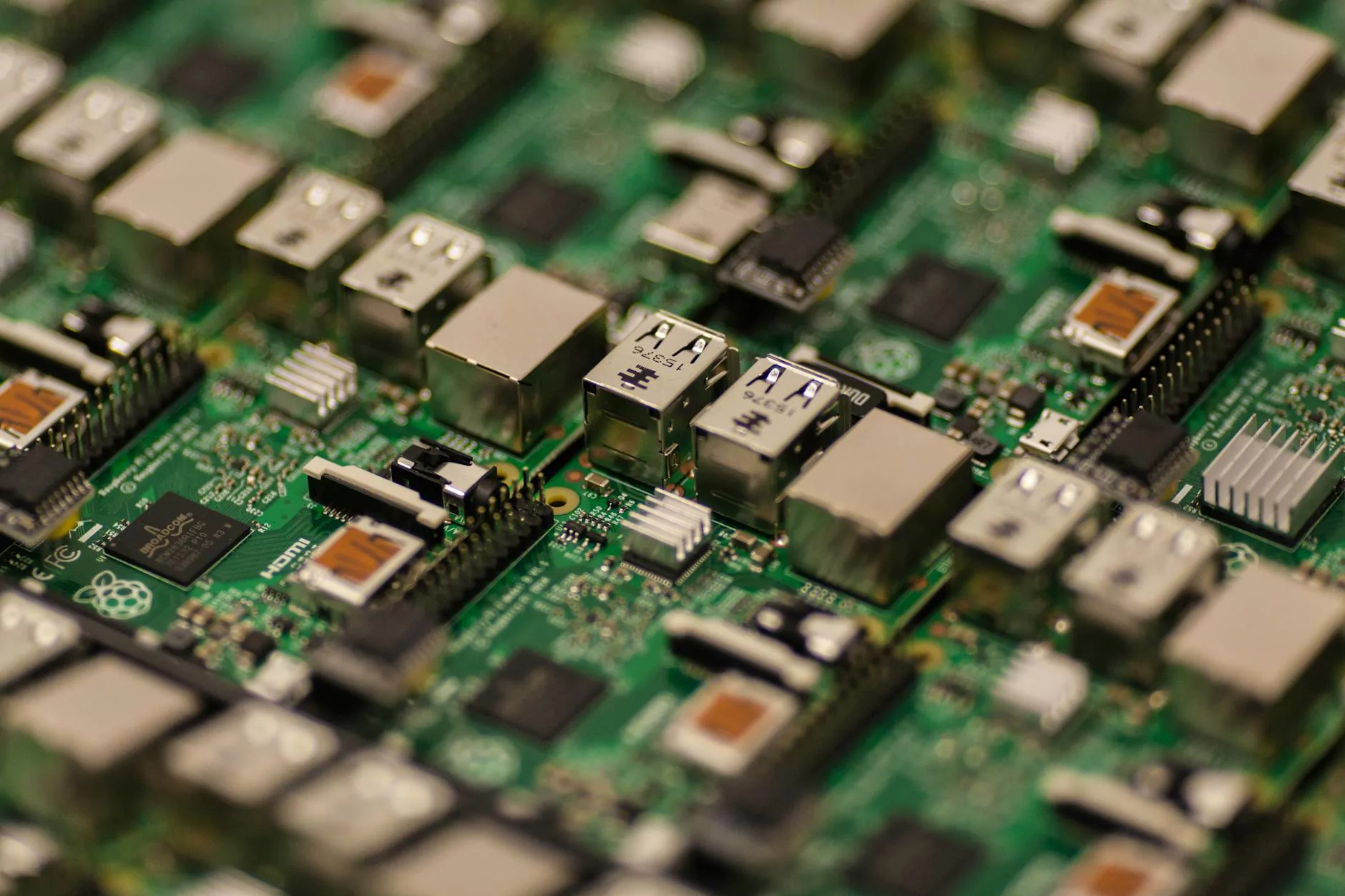

The electronics industry encompasses a vast array of products—ranging from consumer gadgets to sophisticated industrial equipment. As the backbone of modern communication, entertainment, and automation, this sector demands high-quality components, precise manufacturing processes, and reliable supply chain logistics.

Meanwhile, the 3D printing industry has revolutionized product development and manufacturing, enabling rapid prototyping, customization, and complex geometrical productions that were once deemed impossible. Both fields share a common drive towards innovation, efficiency, and scalability, which makes strategic management of materials essential for maintaining competitive advantage.

The Critical Role of Bulk Material Handling in Modern Business Operations

Bulk material handling refers to the systematic process of transporting, storing, controlling, and protecting bulk substances such as powders, granules, and liquids. In industries like electronics and 3D printing, the efficient management of these raw materials significantly impacts productivity, product quality, and operational costs.

Integrating advanced bulk material handling solutions enables manufacturers to streamline their workflows, reduce waste, and enhance safety protocols. Because of the complexities involved—such as material flow characteristics, contamination prevention, and environmental considerations—tailored handling systems are crucial for achieving sustainability and operational excellence.

Why Bulk Material Handling is Essential for the Electronics Industry

The electronics manufacturing process involves handling sensitive components, chemicals, and raw materials like microchips, solder powders, and adhesives. Precise and contamination-free handling is necessary to maintain product integrity.

- Automated Conveyance Systems: Modern electronics factories utilize conveyor belts, vacuum systems, and pneumatic transport to move fragile components efficiently.

- Dust Control and Containment: To prevent static buildup and contamination, specialized enclosures and filtration units are integrated into handling systems.

- Material Storage Solutions: Sophisticated silos, hoppers, and bins facilitate safe storage of bulk chemicals and powders, ensuring consistent supply and minimizing degradation.

Effective bulk material handling in electronics manufacturing translates into reduced downtime, improved quality control, and cost savings. Companies investing in cutting-edge handling technologies often outperform competitors by maintaining higher standards and faster time-to-market.

Bulk Material Handling in the 3D Printing Industry: Enhancing Innovation

The 3D printing sector largely relies on powders and resin materials that demand specialized handling systems. As the industry pushes towards larger production volumes and diverse materials, robust bulk handling solutions become even more paramount.

Key considerations include:

- Material Flow Optimization: To ensure uniform layer deposition and prevent material segregation or clogging during printing.

- Dust Management: Critical for safety and print quality, particularly when handling fine powders such as metallic or ceramic particles.

- Automated Replenishment Systems: To maintain uninterrupted printing processes, reducing manual intervention and errors.

By investing in innovative bulk material handling apparatus such as vacuum transfer units and integrated storage silos, businesses can significantly improve their operational efficiency, reduce waste, and accelerate product development cycles.

Innovative Technologies Transforming Bulk Material Handling

The evolution of bulk material handling technology is driven by the need for higher precision, better safety, and cost efficiency. Leading industry providers, like PolygonMach, offer pioneering solutions tailored to complex demands.

Key technological advancements include:

- Smart Conveyors: Equipped with sensors and IoT integration for real-time monitoring and automated adjustments.

- Modular Silos and Hoppers: Designed for quick installation, easy maintenance, and scalability in response to production needs.

- Energy-Efficient Systems: Utilizing eco-friendly drives and control systems to reduce energy consumption and carbon footprint.

- Contamination Prevention Technologies: Including sealed systems to maintain purity, especially vital in electronics and high-grade 3D printing materials.

Strategic Planning for Optimal Bulk Material Management

Effective business planning must include a comprehensive approach to bulk material handling. This involves assessing material properties, production scale, safety standards, and scalability to choose the right systems.

Best practices include:

- Conducting Material Flow Analysis: To understand characteristics like flowability, cohesiveness, and moisture content for system customization.

- Implementing Maintenance Protocols: Regular inspections, cleaning, and system upgrades to prevent downtime and ensure safety.

- Training Workforce: Providing personnel with the knowledge to operate and troubleshoot handling equipment effectively.

- Integrating Automation: Using control systems that enhance precision and reduce human error.

Choosing the Right Partner for Business Success

Partnering with a reputable provider like PolygonMach offers numerous advantages:

- Customized Solutions: Tailored to meet specific industry needs, ensuring optimal performance and adaptability.

- Expert Consultation: Access to technical experts who understand material properties and operational challenges.

- Cutting-Edge Equipment: Offering the latest in bulk material handling technology to maximize efficiency and safety.

- After-Sales Support: Reliable maintenance, spare parts, and upgrade services to sustain operational excellence.

Choosing a strategic partner ensures your business remains competitive, compliant with safety standards, and positioned for sustained growth in electronics and 3D printing markets.

Conclusion: Elevate Your Business Through Advanced Bulk Material Handling

In sectors as innovative and fast-moving as electronics and 3D printing, efficient bulk material handling is more than a logistical necessity — it is a critical driver of quality, safety, and profitability. Successful businesses are those that recognize the importance of integrating the most advanced handling solutions into their manufacturing processes.

By leveraging state-of-the-art technology, partnering with experienced providers like PolygonMach, and adopting strategic operational practices, organizations can achieve unparalleled efficiency and sustainable growth in their respective markets.

Embrace the future of manufacturing today—invest in innovative bulk material handling solutions that empower your business to thrive amidst industry advancements and evolving consumer demands.