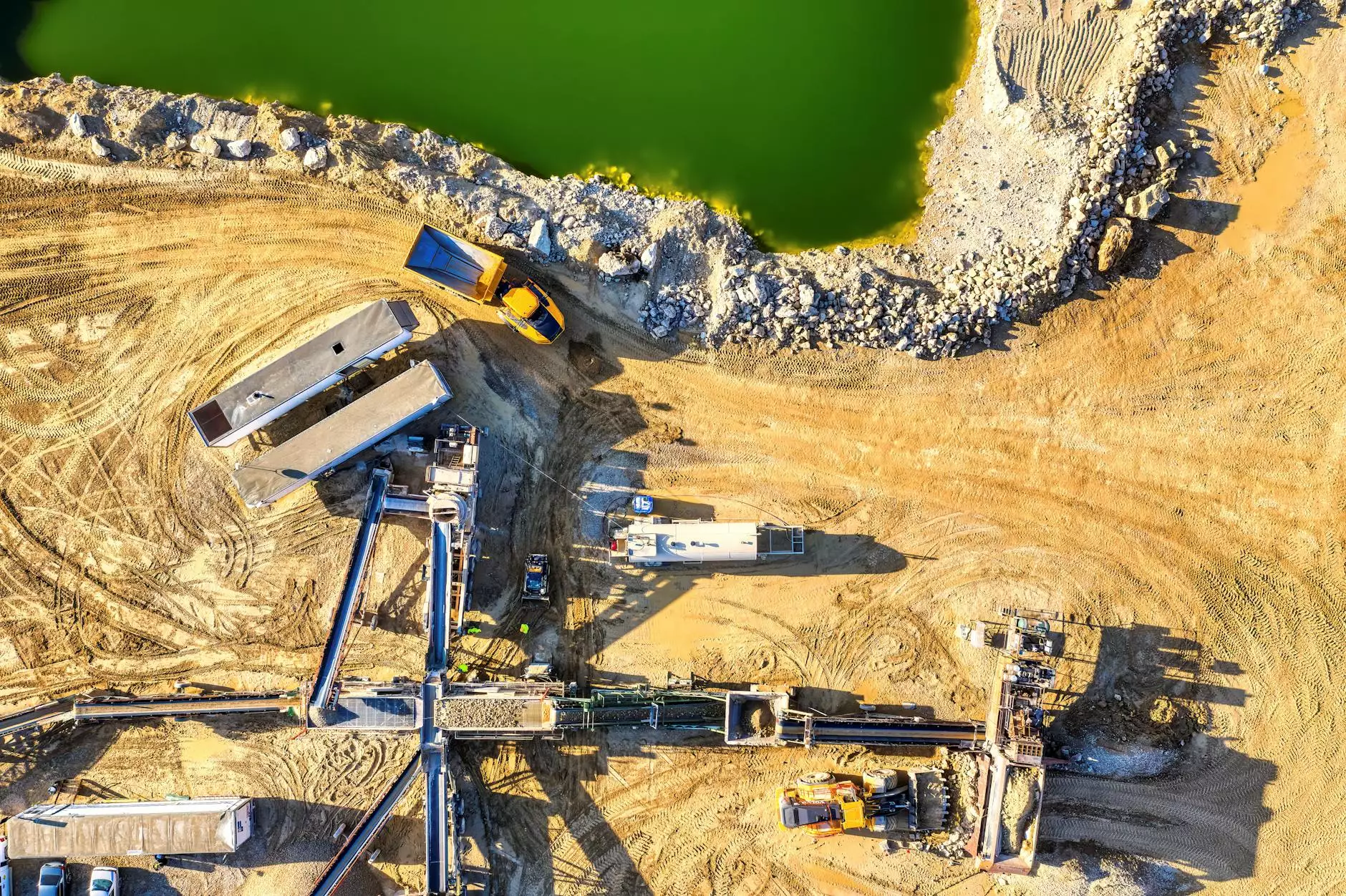

Understanding Hydraulic Excavator Parts: Essential Components for Optimal Performance

In the realm of heavy machinery, hydraulic excavators stand out as crucial equipment for construction, mining, and various other industrial applications. As the demand for efficiency and precision in construction practices increases, understanding the components that enable hydraulic excavators to perform optimally becomes essential. This article dives deep into the world of hydraulic excavator parts, highlighting their significance, functionality, and maintenance practices that ensure longevity and efficiency.

What Are Hydraulic Excavator Parts?

Hydraulic excavator parts are specialized components designed to operate using hydraulic fluid, facilitating motion and power transmission. These parts work in tandem to execute a wide range of tasks, from digging trenches to lifting heavy materials. The principle behind their operation is based on Pascal's law, which states that pressure applied to a confined fluid is transmitted undiminished in all directions.

The Key Components of Hydraulic Excavators

Understanding the fundamental hydraulic excavator parts is pivotal for anyone involved with heavy machinery. Here’s a breakdown of the essential components:

- Hydraulic Cylinder: These are vital for converting hydraulic energy into mechanical energy. They are responsible for the movement of the boom, arm, and bucket.

- Hydraulic Pump: Vital for creating the necessary hydraulic pressure. It draws hydraulic fluid from the tank and sends it to the cylinders.

- Hydraulic Fluid: The lifeblood of hydraulic systems, this fluid transmits force and lubricates the system.

- Boom: The long arm of the excavator that is responsible for reaching out to the desired location.

- Stick (or Arm): Attached to the end of the boom, the stick helps extend the reach of the bucket.

- Bucket: The component that performs the digging, lifting, and moving. Its design varies depending on the application.

- Swing Mechanism: Allows the excavator to rotate in place, providing improved operational flexibility.

- Track System: Essential for mobility, the tracks distribute the excavator's weight and enhance stability.

- Cab and Controls: The operator's workspace, equipped with controls for directing the excavator's functions.

The Importance of Hydraulic Excavator Parts

The significance of each hydraulic excavator part cannot be overstated. Each component plays a critical role in ensuring efficiency, safety, and productivity on the worksite. Let’s explore why these parts are so essential:

1. Performance and Efficiency

When all components of a hydraulic excavator are functioning optimally, the result is enhanced performance. Hydraulic systems are known for their ability to create substantial force when needed while maintaining a smooth operation. This efficiency translates into higher productivity and faster project completion.

2. Safety

Maintaining the integrity of hydraulic excavator parts is vital for the safety of the operator and surrounding personnel. Hydraulic failures can lead to catastrophic failures, making regular maintenance essential. Knowing the functionality and wear indicators for each component can prevent accidents.

3. Cost-effectiveness

Investing in quality hydraulic excavator parts ensures longevity and reduces the frequency of repairs. Proper maintenance can extend the life of the machine, leading to lower operational costs over time.

Common Problems with Hydraulic Excavator Parts

Despite their robustness, hydraulic excavators may face issues stemming from wear and tear or improper usage. Here are some common problems associated with hydraulic excavator parts:

- Leaking Hydraulic Fluid: This can occur at fittings, hoses, or cylinders, leading to reduced operational efficiency.

- Slow or Uneven Movement: Often a symptom of issues with the hydraulic pump or low hydraulic fluid levels.

- Overheating: Can occur due to prolonged use or insufficient fluid levels, which can damage critical components.

- Noisy Operation: Unusual sounds can indicate problems within the hydraulic system, signaling a need for inspection.

Maintenance Tips for Hydraulic Excavator Parts

To keep hydraulic excavators performing at their peak, regular maintenance of hydraulic excavator parts is crucial. Here are some effective maintenance tips:

1. Regular Inspection

Schedule frequent inspections of all hydraulic components. Look for signs of wear, leaks, and damage. Early detection can prevent larger issues down the road.

2. Change Hydraulic Fluid Regularly

Hydraulic fluid should be changed at recommended intervals to prevent contamination. Dirty fluid can cause significant damage to hydraulic components.

3. Clean Air Filters

Keeping air filters clean ensures that dust and debris do not enter the hydraulic system, which can lead to component failure.

4. Monitor Temperature

Pay attention to operating temperatures of hydraulic fluid and components. Overheating can indicate problems that must be addressed promptly.

5. Use Genuine Parts

When replacing hydraulic excavator parts, opt for genuine or high-quality aftermarket parts. This helps ensure compatibility and reliability.

Choosing the Right Hydraulic Excavator Parts

When it comes time to replace or upgrade hydraulic excavator parts, the choice you make is crucial to the long-term functionality of your equipment. Here are key factors to consider:

1. Compatibility

Ensure that any new part is compatible with your specific excavator model. Refer to the manufacturer’s guidelines or consult with a specialist if unsure.

2. Quality and Durability

Prioritize high-quality parts that can withstand the rigors of heavy use. Look for reviews and feedback from other users to gauge durability.

3. Supplier Reputation

Purchase from reputable suppliers, like Shop Hydraulic America, that offer a wide selection of hydraulic excavator parts and provide excellent customer support.

The Future of Hydraulic Excavator Parts

The landscape of heavy machinery is evolving rapidly, driven by technological advancements. The future of hydraulic excavator parts is likely to be influenced by the following trends:

1. Smart Technology Integration

The incorporation of IoT (Internet of Things) technologies into hydraulic excavators will lead to smarter machines capable of predicting maintenance needs and operational efficiencies.

2. Enhanced Materials

With advancements in material science, we can expect more durable, lightweight materials in the manufacturing of hydraulic parts, leading to improved performance.

3. Sustainability

As companies aim to reduce their carbon footprint, more emphasis will be placed on sustainable practices in the manufacturing and usage of hydraulic excavator parts.

Conclusion

In the dynamic world of construction and heavy machinery, hydraulic excavator parts remain fundamental to operational success. With careful attention to the maintenance and selection of these components, businesses can enhance performance, ensure safety, and achieve cost savings. As technology advances, staying informed and adapting to new developments will be vital. Whether you're an operator, a mechanic, or a business owner, recognizing the importance of these parts will position you for success in your projects.

For all your hydraulic excavator parts needs, Shop Hydraulic America offers a comprehensive range of quality options to help you keep your equipment running smoothly.