The Future of Street Sweeper Manufacturing: A 3D Printing Revolution

In the fast-paced world of industrial manufacturing, innovation knows no bounds. The realm of street sweeper production is no exception, with companies embracing cutting-edge technologies like 3D printing to revolutionize the way these essential machines are designed and built.

3D Printing in Street Sweeper Manufacturing

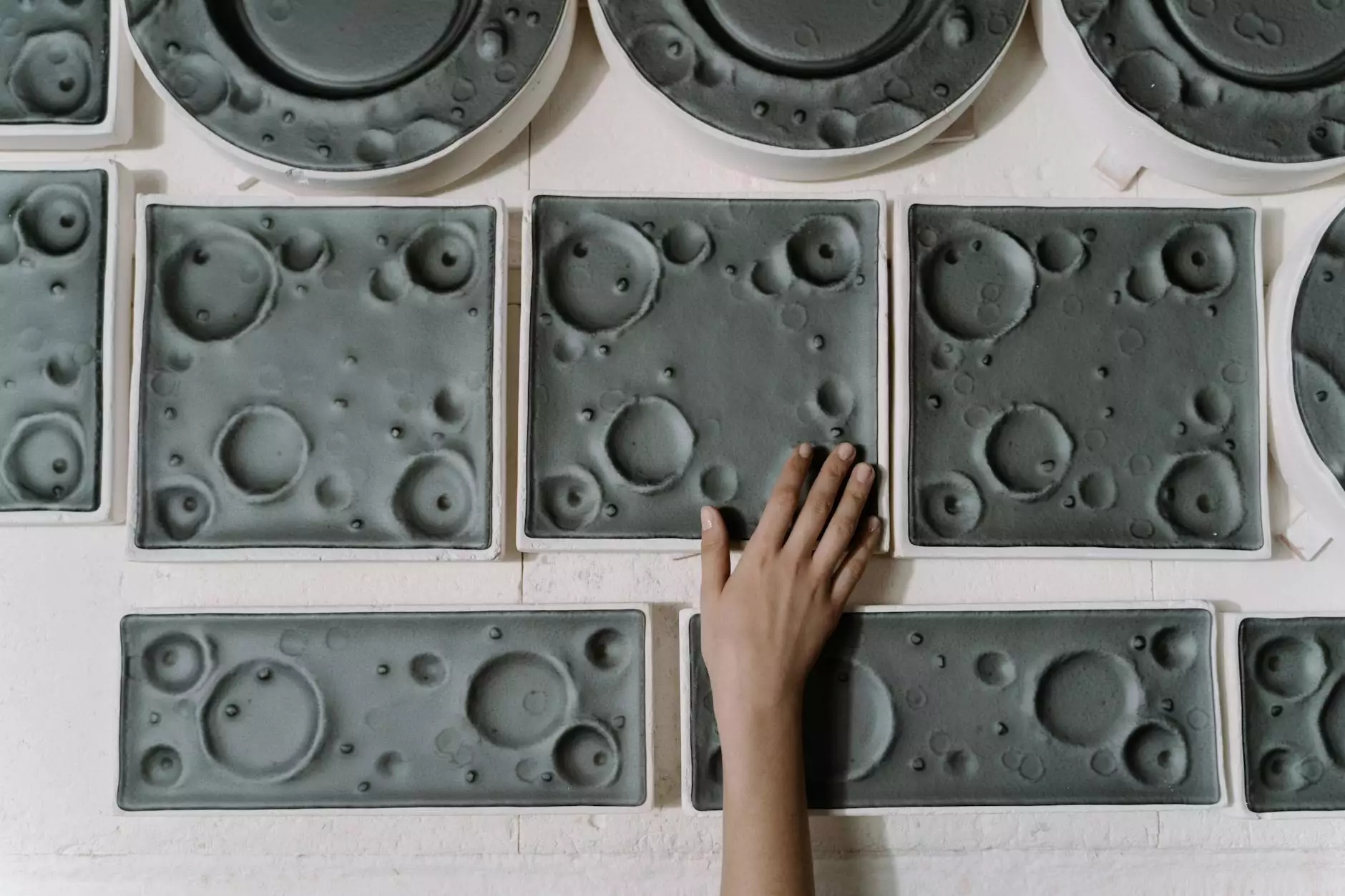

The integration of 3D printing technology in the street sweeper manufacturing process has opened up a world of possibilities. Traditional manufacturing methods often involve time-consuming and costly processes, but with 3D printing, companies like ceksansweepers.com can create intricate parts with precision and efficiency.

Street sweeper manufacturers are leveraging the benefits of 3D printing to prototype new designs quickly, test various configurations, and ultimately streamline the production process. By digitally crafting components layer by layer, these companies can reduce waste, minimize production errors, and accelerate time-to-market for their products.

The Impact of 3D Printing on Product Customization

One of the key advantages of incorporating 3D printing in street sweeper manufacturing is the ability to customize machines according to specific requirements. Whether it's optimizing the size and shape of cleaning brushes or fine-tuning the suction power, 3D printing enables unparalleled flexibility in design.

At ceksansweepers.com, customers have the opportunity to work closely with the design team to create bespoke street sweepers tailored to their unique needs. This level of customization not only enhances the performance of the machines but also fosters long-term client satisfaction and loyalty.

Enhancing Sustainability with 3D Printing

Sustainability is a top priority for modern businesses, and the adoption of 3D printing in street sweeper manufacturing aligns perfectly with this ethos. By utilizing additive manufacturing techniques, companies can significantly reduce material waste and energy consumption compared to traditional manufacturing methods.

Ceksansweepers.com takes pride in their commitment to environmental responsibility, leveraging 3D printing to create eco-friendly street sweepers that deliver high efficiency while minimizing their carbon footprint. This dedication to sustainability not only benefits the planet but also resonates with environmentally-conscious customers seeking greener solutions.

Driving Innovation and Competitiveness

Embracing 3D printing technology sets street sweeper manufacturers like ceksansweepers.com apart from the competition. The ability to innovate rapidly, respond to market demands swiftly, and deliver custom solutions gives these companies a competitive edge in the industry.

With an unwavering focus on quality, performance, and customer satisfaction, street sweeper manufacturers leveraging 3D printing are paving the way for the future of industrial manufacturing. Ceksansweepers.com stands at the forefront of this evolution, combining state-of-the-art technology with unparalleled expertise to redefine the landscape of street sweeper production.

Conclusion

As the world of street sweeper manufacturing continues to evolve, the integration of 3D printing is revolutionizing the industry, driving innovation, customization, and sustainability. Companies like ceksansweepers.com are at the forefront of this transformative trend, harnessing the power of additive manufacturing to create superior products and stay ahead of the curve.

For businesses seeking cutting-edge solutions and superior quality in street sweeper manufacturing, partnering with a company that embraces 3D printing technology is the key to unlocking endless possibilities and staying competitive in an ever-changing market.